Girders are built for carrying dynamic loads and rolling loads. This is what makes them preferable for bridge construction, where load amount is not constant. Dynamic loads are those that exert varying amounts of force upon a structure. Dynamic loads are contrast with static loads, which exert the same amount of force at all times. It takes a special kind of beam to withstand dynamic loads with consistent, unfailing strength. Girder beams have the ideal structure and capabilities for withstanding heavy dynamic loads. In general, effective spans of about 25 to 150 meters are applied, but the Costa e Silva Bridge (Brazil) was built with the longest effective span of 300 meters. JFE Engineering has the most experience in the manufacture and construction of bridges of this type.

|

| Cross Section of a Girder (Box Girder) |

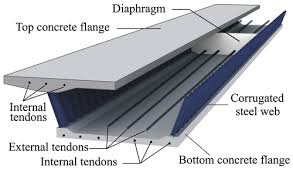

Diaphragms are adopted in concrete box girder bridges to transfer loads from bridge decks to bearings. Since the depth of diaphragms normally exceeds the width by two times, they are usually designed as deep beams. However, diaphragms may not be necessary in case bridge bearings are placed directly under the webs because loads in bridge decks can be directly transferred to the bearings based on Jorg Schlaich & Hartmut Scheef (1982). This arrangement suffers from the drawback that changing of bearings during future maintenance operation is more difficult. In fact, diaphragms also contribute to the provision of torsional restraint to the bridge deck.

Bridges where the deck slabs and the main girders work together to resist loads are called composite girder bridges, and bridges designed to resist loads with the main girders only are called non-composite girder bridges .There is no difference between how a beam and girder behave. Both have the same goal – to resist forces by bending. A girder is simply a type of support beam. It is the main horizontal support of a structure or the large beam that supports smaller beams. Like beams, girders typically have I-shaped cross sections composed of two load-bearing flanges and a web for stabilization. Girders may also take on a box orZ shape, as well as other forms. The industry typically uses girders to build bridges, as well as trusses for buildings and other structures.

|

| View of Girders |

A girder is a primary beam. Its main job is to transfer loads to the columns upon which it rests. A beam is a secondary beam. Its main job is to transfer its loads to girders, which then transfer the load to the columns. Beams bend to accommodate shear stresses, while girders are more stiff to support the small beams. When differentiating between a beam and a girder, determine the component’s main job. If it’s to transfer load to a larger beam, it’s just a beam. If it’s to transfer load directly to the columns it sits upon, it’s a girder.

* images from ascelibrary.com

Comments

Post a Comment